Choosing the right submersible pump for your water well.

“Hmm, which of these pumps should I buy? This 1 HP FPS well pump or this 1 HP Goulds well pump?” Many folks are scratching their heads about purchasing a well pump while searching at the hardware store or online. There are many variables involved when selecting the appropriate submersible well pump for your home. Some water wells are over 800 feet (250m) deep while other wells are 80 feet (25m) deep. Water demands vary from just a few gallons per minute to hundreds of gallons per minute depending on if you are supplying water for a small cottage or a large estate. In this overview we are going to explore the factors affecting the selection of the correct submersible well pump for your water well. If you are interested in where to buy quality submersible well pump equipment, check out this article before you buy equipment online or at a hardware store!

Aren’t Pumps sized by Horsepower?

Don’t fall into the trap of thinking you need a certain horsepower of pump. You’ll notice the two amazon links to the right for 1/2 HP pumps. One of these pumps flows 5 GPM and the other flows 10 Gallons Per Minute! Is this just a mistake or oversight in the description? No! These pumps have different impellers and create different flow and pressures! A 1/2 HP 5 GPM pump creates more pressure and less flow than a 1/2 HP 10 GPM pump. In the pump industry we typically designate pumps by both the flow rate and horsepower required. Another, more precise, way to designate a pump is by what is called the “design point” of the pump. The design point includes the flow rate needed and the amount of pressure (head) that the pump needs to produce. When specifying the correct pump, it is more important to specify the amount of pressure and flow required than the horsepower required for the motor. Some pumps may be extremely efficient and be able to provide the flow and pressure with less power and thus require a lower horsepower motor than their cheaper competitors. While a more efficient pump may cost more, remember that it is working for several hours each day. The cumulative power savings over the next 7-10 years will more than pay for the more expensive & efficient pump when you factor in the decreased energy consumption. The cheap pump may be much more expensive in the long run.

Now, you’re probably asking. OK, I get it, choosing a pump by simply looking at horsepower can be very problematic, so what do I do? How do I know how much pressure or flow is required? We’re glad you asked! Hang on because now we’re going to help you understand how to calculate the design point and then choose a pump based on the design point, then we’ll finish up by giving some examples of pumps available online that seem confusing and help give you some of the tools you’ll need to make sense of it.

Basic Design Point Calculation.

As we just mentioned, the design point for a submersible well pump is the combination of how much pressure the pump needs to provide and the quantity of water the pump is expected to supply at that pressure. It is important to understand the difference between flow and pressure because they are distinctly different aspects of fluid dynamics.

Flow has to to with the amount, or quantity of water that flows in a given period of time. In the US this is typically measured in Gallons per Minute (GPM). If you well can produce 20 gallons per minute, that simply means that 20 gallons of water are available for extraction from your well every 60 seconds.

Pressure has to do with how much force the water exerts because of the effects of gravity and is measured in units of pressure. Your water pressure, just like tire pressure, is measured in Pounds per Square Inch (PSI) in the US. When working with water in our industry we often convert the pressure to a unit call ‘head’. Water head pressure simply means that we are talking about a unit of pressure that has units that are measured in feet of vertical water column. The higher the column of water, the more pressure there will be! 1 PSI = 2.31 ft of head. This means that a pipe, tank or any other container of water that has 2.31 ft of water in it will exert a pressure of 1 PSI at the bottom of that pipe, tank, etc… Believe it or not, it doesn’t make any difference how big around the pipe, tank or container are; the only factor that influenced the amount of pressure is the height of the water in the pipe, tank or container!

Here are a few examples that illustrate design points:

-Joe Waterman needs a pump for his well that will provide 15 Gallons per minute for his house/landscaping needs. His well is 400’ deep. He also wants 60 PSI (140’) of water pressure available at the house. Joe will need a pump that can pump 15 gallons per minute at 540’ (400’+140’) of Head or 234 PSI. ( note that ‘ is the shorthand for “feet”)

-Betty Tinker wants to pump water from her 5 gallon per minute well that is 300’ deep (130 PSI) up a hill to her storage tank that is 200’ above the well (87 PSI). She will need a pump that will pump 5GPM at 500’ of Head (216 PSI).

To get the design point for your well pump, you or your well pump contractor should review data from the well driller's log to find well depth and water depth in addition to expected water flow from the well. If there are any well flow tests, these should be reviewed too. Next the amount of water required to supply the housing, irrigation and other needs should be calculated. Lastly, your contractor should look at the sizes of pipe in the ground and the size of pipe going down to the well pump to calculate a factor called “friction loss.” The piping exerts friction on the liquid that flows through it, the faster the liquid flows, the more the losses from friction! While this seems like it could be minimal, it adds up as the lengths of pipe add up and can really limit flow rates if it isn’t accounted for in pump or pipe sizing.

Pump Selection

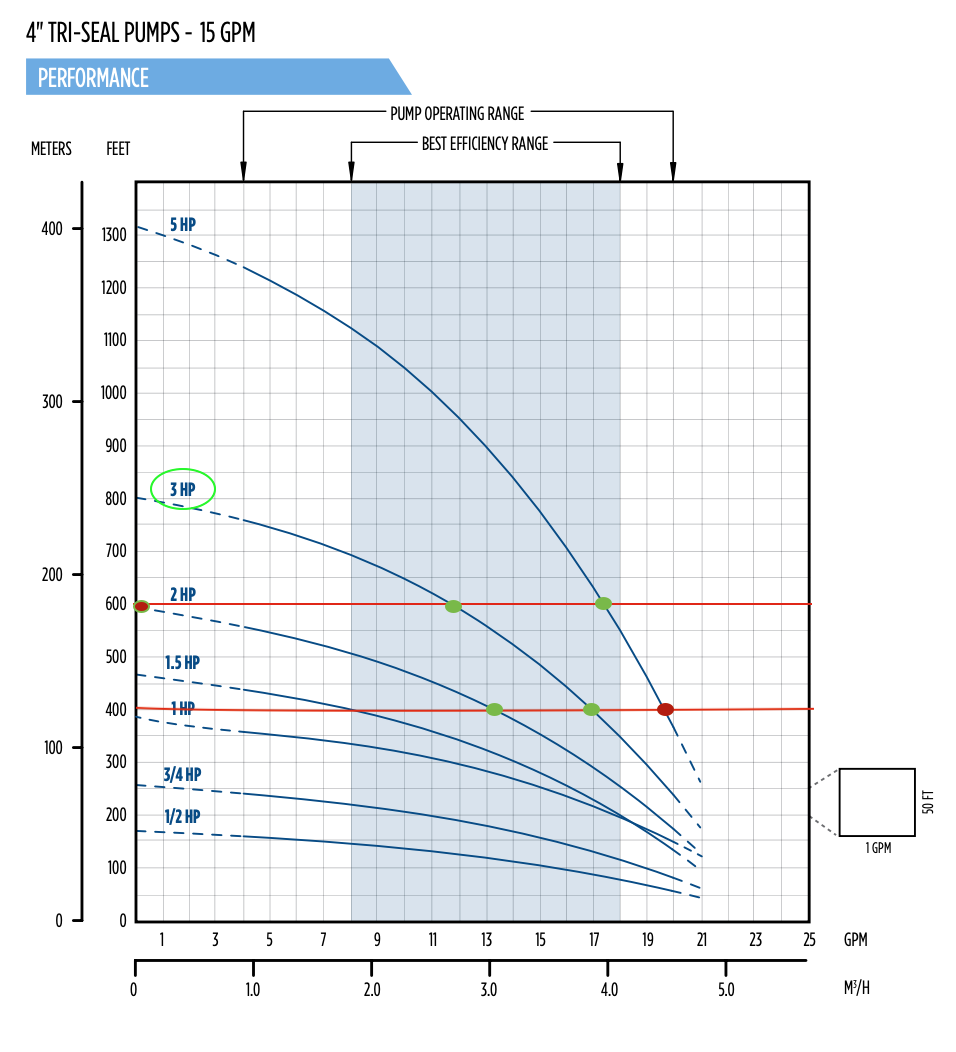

Once you or your well pump contractor has reviewed the pertinent information and established an adequate design point, it is time to review technical bulletins called “pump curves” from well pump manufacturers. A pump curve from Franklin Water is pictured below, you can check out their entire submersible pump catalog too. As you move from left to right on the chart you see that as flow from any given pump increases, the amount of pressure that pump can produce decreases. This is normal for any centrifugal type pump, including submersible well pumps. This relationship for any pump is called its “curve.” Careful review of these pump curves can help you/your well pump contractor determine which pump will be best for your application.

Let’s use an example to illustrate proper pump selection. Let’s say that you have a well that is 400’ deep with a static water level (water level in the well when the pump is turned off) that is at 200’ below ground. The water level in the well drops to 300’ below the surface of the ground when the well is pumped at 15 Gallons per minute. This water well supplies water to a house that is on a hill that is 50’ above the well and the house needs to have 50 PSI (115’) of pressure available at the house. The house has minimal landscaping and 15 GPM is more than adequate to meet household demands. The pipes supplying the house have friction loss values of 35’ TDH at a flow rates of 15 GPM.

The total dynamic head (TDH) is calculated twice, once for the best case scenario with a high water level in the well and again with the worst case scenario, with a low water table in the well:

Best Case Design Point= 200’+50’+115’+35’=400’ TDH @ ~15 GPM with well not recently in use

Worst Case Design Point=400’+50’+115’+35’=600’ TDH @ ~15 GPM with well in use for a period of time

With this information in hand, it is time to look at some pump curves and choose the most suitable one!

There are several pumps that will provide ~13-17 Gallons Per Minute between 400’ and 600’ THD region bracketed by the upper and lower red lines! These red line represent your best and worse case scenarios that were calculated for the design points. Blue shading indicates “best efficiency operation”, solid pump curve lines indicate normal operating flow rates while dashed pump curved lines indicate flow rates that the pump should not be operated at for long periods of time.

The optimal pump is the one that delivers the water and pressure needed while keeping the pump operating in the optimal efficiency zone.

If you look at the 2 HP pump curve you notice this pump will struggle to keep up with both pressure and flow demands and it is highly likely it will work outside of the “optimal efficiency zone” shown in the blue background of the pump curve chart.

Now let’s look at the 5 HP pump curve. While this pump can meet the flow and pressure demands, its expected area of operation also falls outside of the blue efficiency zone on the right hand side. Another significant factor is that larger pumps cost more money! This large pump also requires larger wire and larger pipe to hold the increased weight of this size pump, pipe, water & wire. When you add up the larger pump, wire, & pipe you may have more than doubled the installation costs. A bigger, higher horsepower pump is definitely not “better” in this case as it will hurt your wallet for the initial purchase and keep your wallet skinny with unnecessarily low efficiency/high energy consumption in the future. In addition, if the well cannot provide 20 gallons per minute, the pump could over-pump the well and start to suck air! This could damage the pump and it would then need to have a special controller installed to turn it off when it runs out of water. The “bigger is better” mentality creates lots of problems and expense down the road and should be avoided! When in doubt, BIGGER IS NOT BETTER when it comes to submersible pumps.

Now, let’s check out the 3 HP pump curve. At 400’ TDH it is producing 17 GPM and at the 600’ TDH it is producing 12 GPM, both of these points are within the blue “efficient zone” and this pump should be ready to meet your needs in a cost effective and energy efficient manner.

Check out part 2 of this blog for more information on they type of motor (there are several options) wire and drop pipe to use as you plan the best submersible well pump install for your needs. These choices can cost or save you big $. You may also want to check out Are You Pouring Money Down Your Well? and Avoiding Online Pump Confusion for additional insights when into submersible well pumps.

Oakville Pump Service has trained professionals with decades of experience. Our professionals will help you select the correct submersible well pump for your residential, commercial or agricultural well in the Napa and Pope Valley areas. OPS knows pumps and pump manufacturers. Whether your water is deep, sandy, hot, or full of minerals; we can help you choose the pump best suited for your application. Our team will ensure you get the pump that will last the longest, work the most efficiently and be installed in a manner that represents the highest industry standards! Call us today at (707)944-2471

If you have additional questions you’d like our blog to address, please contact us and we will try to address them in future blogs!